With advancement in digital textile technology, the printing industry has significantly impacted the custom garment sector. Especially with Direct-to-Film (DTF) printing, the personalized clothing market has entirely transformed.

But, exactly what is DTF printing, and how it turned out to be a game changer technique in the clothing industry? This blog will guide you through the essentials that will help you make informed decisions, whether you are considering a career in the DTF printing process or simply looking to get your ideas printed.

What is DTF Printing?

DTF printing (Direct-to-Film) is the latest technique for transferring vibrant and high-quality graphics onto a variety of materials. What is DTF printing? It involves printing a design onto a particular film, which is then covered with adhesive powder and heat pressed onto the garment.

Unlike standard Direct-to-Garment printing, DTF printing can be printed on polyester, cotton, mixes as well as dark fabrics. What is DTF print? This modern method is becoming increasingly popular that even other printing means find it difficult to accomplish.

How to do DTF Printing?

DTF printing involves certain steps which you need to follow to achieve a perfect result.

- Design your artwork: Make a digital design on a computer and adjust for color sizes and other specifications.

- Print on DTF film: Instead of printing the fabric, a DTF printer prints a unique film. Printing a layer of white ink to serve as a foundation for printed colors is its first phase.

- Use adhesive powder: An adhesive powder is applied to the film. This glue will adhere the design to the fabric during transfer.

- Cure the print: The printed film will be prepared for placement on the fabric after it has been heated to cure the adhesive.

- Transfer the print: At the end, heat press the design onto the fabric

What is the Best DTF Printer for Small Business?

The DTF printing process grants small business owners to print designs on a wide range of fabrics like cotton, leather and polyester. Since a company is not restricted to a single form of printing and can adapt to the needs of its client, it also creates huge opportunities for custom printing services.

Also Read: How Much is a DTF Printer? Exploring Price vs. Performance

In the below list, we will explore what is the best DTF printer for small business that would be easy to use for entrepreneurs.

1. Punehod A3 DTF Printer

This printer is a high-quality and professional grade printing machine that is ideal for small business establishments with minimal space. The affordable rate of Punehod A3 DTF Printer gives good color accuracy prints on the fabrics.

If you are asking what is a DTF printer? It is a type of printer that uses DTF methods to print designs onto the transfern film. It is used in both film and garment printing. With a refillable tank, it helps to reduce waste and save cost in the long run.

2. Kodak DTF Printer

Kodak DTF printers can print a broad range of fabrics including nylon, blends, natural fibers, polyesters and many more. It offers better quality printing with rich colors and resolution. As it is easy to use, it reduces the cases of blockages by including automatic circulation of ink.

Additionally, this printer minimizes the initial investments in the hardware that makes it an attractive option for businesses looking to expand their services.

3. Epson SureColor F2100

If you’re wondering what is the best printers for small business, then Epson SureColor F2100 is the perfect choice. It has the most detailed technologies installed which enables the printer to provide both large-scale production and accurate design work.

Also Read: DTF Care Instructions: Washing, Pressing, and Temp/Time Guidelines

The printer performs an automatic cleaning in every 5 operational hours to offer low maintenance. Its user-friendly and high print quality is great for bulk printing.

4. L1800 DTF Printer

L1800 DTF printer low cost and excellent print quality is a good option for small business. It increases the efficiency of DTF printing by introducing a roll feeder and auto heat station that reduces paper jam problems.

The printer's versatility, ease of use and minimal maintenance makes it a best option for various industries and applications.

Why is DTF Printing a Game Changer in the Custom Apparel Industry?

The DTF meaning printing (Direct-to-film) has changed the custom garment industry by offering a powerful tool for businesses to meet the growing demand for personalized and printed products, while also providing customers with endless design possibilities and high-quality results.

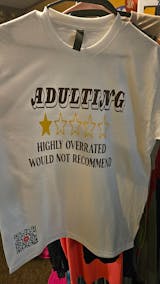

With DTF printing, you can easily transfer your own designs, images, or text onto clothing products that allow for endless creative designs.

Also Read: How to do DTF Transfers: Mastering the Art of Custom Prints

Conclusion

DTF printing introduces new doors for entrepreneurs, small business and enthusiasts of customized garments by printing vibrant, long-lasting images on various kinds of textiles. It is a game-changer because of its affordability, usability and excellent print quality which eliminates the need for costly equipment.

Take your printing to new heights with cutting-edge DTF technology. Visit DTFIL to reshape your DTF printing today!

FAQs

Is DTF better than sublimation?

DTF printing is better than sublimation in a few aspects. For instance, DTF printing has the ability to print on dark and other fabrics, as well as it has relatively lower cost and maintenance. Whereas in sublimation, it can produce vibrant colors and durable prints on polyester only.

Is DTF printing good quality?

DTF printing is known for delivering top-notch quality, durable and vibrant prints with excellent production of graphics and details that makes it a best choice for textiles and custom apparels.

How long does DTF printing last?

DTF printing can last any 50-100 wash cycles and up to 2 years of regular use. Depending on fabric type, washing dry and transferring quality with proper handling.

What is DTF printing used for?

Direct-to-film (DTF) printing is used to allow for efficient and versatile transfer of designs onto various fabrics without the need for intermediate steps.

How to choose a DTF printer?

To choose the best DTF printer, look into factors such as print quality, cost of printer, ink, film and maintenance. And make sure that it prints at high rate speed and is durable.

What is the best printer for DTF transfer?

The best printer for DTF transfer is Epson sure color F2100, L1800 DTF printer, Kodak DTF printer and many more.

How much does DTF printing cost per shirt?

DTF printing cost per shirt ranges $2 to $12 per shirt, depending on the print size, materials, printer efficacy and operating costs with factors such as shirt quality, print complexity and others.