How Your DTF Transfers Are Made

1. Prepress

Our team of specialists carefully reviews your artwork before it's processed through our in-house prepress software for printing.

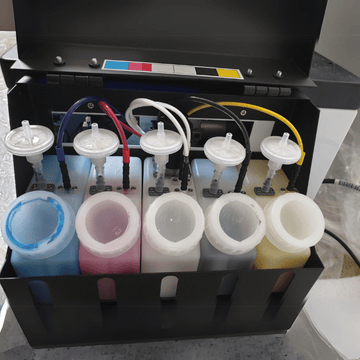

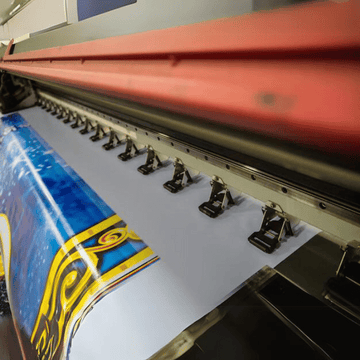

2. Print

Our top-of-the-line production printers boast dual head 2400 dpi print heads, ensuring impeccable quality for your artwork. As your art is printed, an automatic addition of a white under base layer and heat-activated adhesive takes place.

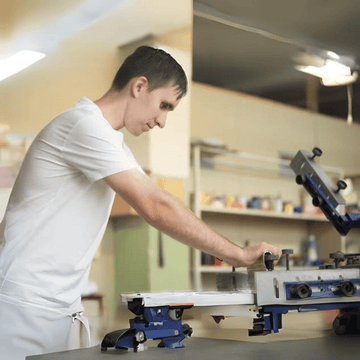

3. Powder

In the next step of the process, the print is coated with a fine layer of DTF-specific powder (TPU powder) after which the printed adhesive is coated.

4. Cure

The printing and powder are heated to a precise temperature to fuse them together, ensuring maximum durability.

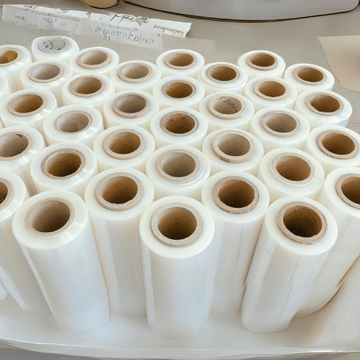

5. Your DTF Transfer

Following a thorough inspection, your transfer is now fully prepared for packaging and direct shipment to your address.